|

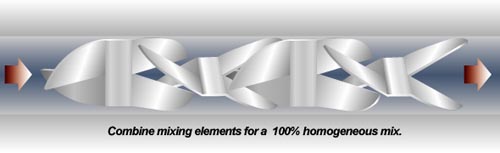

JDMIX Static Mixers

for Your Inline Blending Needs

A Static Mixer is a fixed arrangement of baffles enclosed in a pipeline. The velocity of the process stream flow provides all the mixing energy required for each application. No horsepower is required, so energy savings are always in excess of 90%. There are no moving parts, so expensive maintenance is not required. There is no need to stock spare parts, and motionless mixers are very durable. They have life spans as lengthy as any elbows or turns in your process stream flow.

A Low Cost Solution

Capital cost for a static mixer is very low compared to mechanical mixers. Installation costs for mechanical mixers often are more expensive than the unit itself. With a static mixer, you simply flange or thread the spool piece in place in your pipeline, and expensive installation costs are avoided.

The engineering cost of designing a static mixer in your plant is extremely low. Simply knowing the flow rates, specific gravities, and viscosities of the products you are blending, along with pressure drop restrictions and space constraints is all the detail your engineering staff is required to provide. With this information, the JDMIX team can properly size a static mixer for 100% homogenous mixing for your specific application.

Designed to Meet Your Needs

The static mixer design that JDMIX, Inc, manufactures has been used in thousands of applications in every industry worldwide. They are installed in the pulp and paper, oil and gas, chemical, plastics, food and water treatment industries. Each static mixer is designed around the specific parameters of the customer.

To Request a Static Mixer Quote online, click here.

Home | Products | Applications | Operation | Contact